Medical printed circuit board assemblies sit at the core of diagnostic, therapeutic, and patient monitoring equipment.

Any defect at board level can lead to inaccurate readings, device malfunction, or direct patient harm.

Patient safety drives strict expectations around how boards are built, tested, and documented.

Traceability and documentation function as mandatory regulatory controls rather than optional quality tools.

Legal obligations require manufacturers and suppliers to prove how each board was:

- Produced

- Tested

- Released

International standards and federal regulations define how every component, process step, and decision must remain visible across the product lifecycle.

ISO 13485 and FDA quality system requirements shape daily manufacturing practices by enforcing disciplined recordkeeping, risk control, and accountability across design, production, and service phases.

Regulatory Framework for Medical PCBA

Regulatory oversight defines how medical printed circuit board assemblies are designed, manufactured, documented, and released.

Compliance expectations shape supplier selection, internal processes, and long term product support.

Regulatory alignment also determines audit outcomes and market access across regions.

ISO 13485 Overview

ISO 13485 establishes a quality management system tailored specifically for medical devices and related assemblies.

Compliance requires risk-based thinking embedded into daily operations, formalized procedures governing manufacturing activities, and complete records supporting each finished unit.

Quality planning, execution, and verification remain tightly connected under this standard.

ISO 13485 compliant suppliers must deliver measurable controls across multiple operational areas. Expectations include the following operational requirements:

- Full traceability linking components, processes, and personnel

- Formal Device History Record systems are maintained per unit

- Design and process FMEA applied to identify and reduce potential failures

Corrective and Preventive Action programs support continuous monitoring, structured root cause analysis, and long-term process improvement.

CAPA effectiveness depends on accurate data collection and timely feedback loops.

ISO 13485 also enforces risk control, performance validation, and traceability across production activities.

Process capability metrics, verification steps, and documented acceptance criteria ensure repeatable and auditable quality output. Manufacturing decisions remain evidence-based and controlled.

Other Relevant Standards

Multiple regulatory frameworks interact with ISO 13485 and influence medical PCBA manufacturing strategies.

FDA 21 CFR Part 820 establishes the Quality System Regulation governing medical devices within the United States.

Requirements focus on product identification, lot control, and traceability across:

- Manufacturing

- Inspection

- Testing

- Distribution

Audit readiness depends on rapid access to historical data tied directly to finished units. Key focus areas include the following controls:

- Identification of materials and subassemblies

- Lot and serial number management

- Retention of inspection and test records

EU MDR 2017/745 increases expectations related to traceability, clinical evaluation support, post market surveillance, and technical documentation.

Manufacturers must demonstrate transparent control over materials, suppliers, and production records throughout the device lifecycle.

IEC 60601 applies to medical electrical equipment and addresses protection against electrical shock, mechanical hazards, and system failures.

Compliance influences board layout, insulation strategies, spacing rules, and reliability testing protocols. Electrical safety considerations directly affect component selection and assembly validation.

Companies experienced in high-reliability sectors, such as automotive PCB, often bring robust process controls and traceability systems that are adaptable to medical applications.

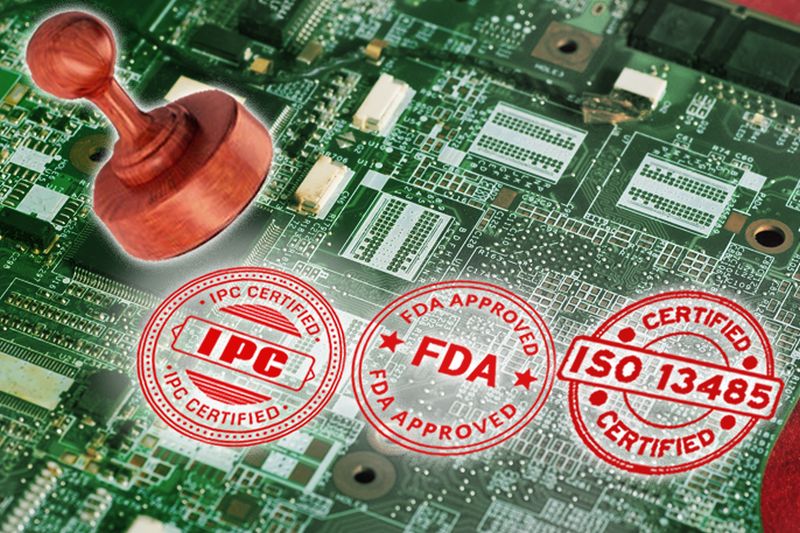

Compliance and Certification

Certification serves as proof that operational systems meet regulatory expectations.

Medical device organizations gain measurable value by partnering with electronics contract manufacturers holding ISO 13485 certification.

Certified partners operate under controlled environments supported by validated equipment and trained personnel.

Traceability databases using barcode driven systems connect materials, work orders, and inspection results into a single data structure. Evidence packages supporting compliance typically include several documented elements:

- Electrical and functional test results

- Inspection and verification records

- Technician qualifications and training history

Certification signals audit readiness and consistent adherence to medical device manufacturing requirements across programs and production volumes.

Documentation Essentials in Medical PCBA

Documentation supports accountability, risk management, and regulatory confidence.

Records demonstrate how quality objectives translate into controlled manufacturing actions.

In medical PCBA production, documentation serves as both operational guidance and legal evidence.

Device History Record (DHR)

Device History Records provide complete evidence showing how each PCBA was built and verified.

Required elements include purchase orders tied to materials, certificates of compliance supporting component quality, test and inspection results validating performance, and technician logs documenting human involvement.

Every board requires a complete Device History Record aligned with ISO 13485 and FDA expectations.

Missing or incomplete records represent regulatory risk and complicate field investigations.

Document Control Systems

Document control systems maintain accuracy and consistency across manufacturing documentation.

Version control ensures only approved drawings, bills of materials, and work instructions reach production.

Change control logs capture revisions, approvals, and implementation dates for process updates.

Manufacturing logs and cleanroom records must align with environmental controls, process parameters, and component lifecycle data.

Controlled documentation prevents unauthorized changes and supports audit readiness.

Work Order Traceability

Work order traceability connects finished serial numbers back to original work orders and purchase orders.

Each serial number links to material sources, assembly dates, and inspection outcomes.

Key traceability elements include identification of component suppliers, names or identifiers of technicians involved at each stage, and recorded completion of every manufacturing step.

Full linkage supports rapid investigation and targeted containment actions.

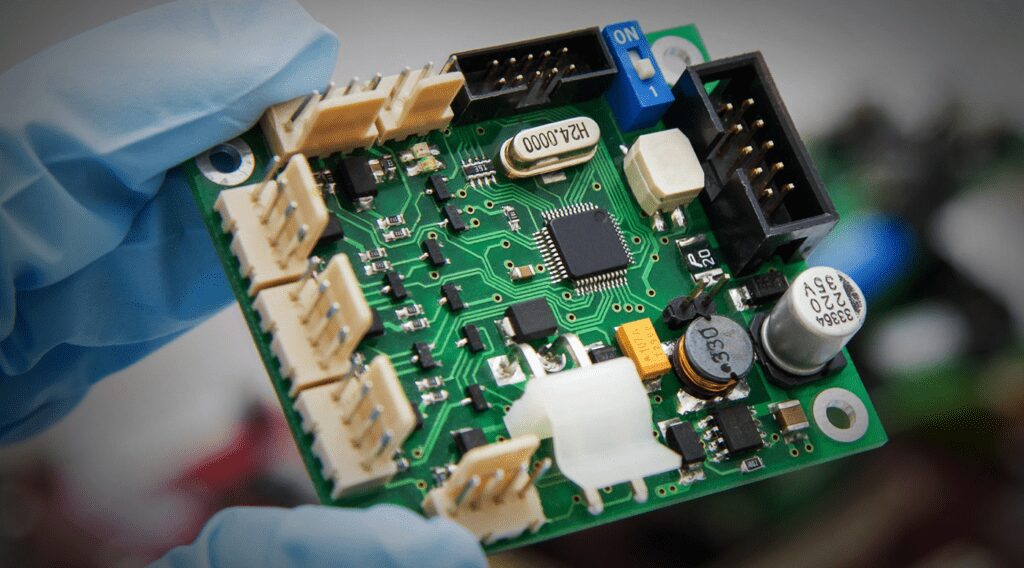

Traceability in Medical PCBA

Traceability refers to the capability to track each part, process step, and individual involved across a PCBA lifecycle.

Materials, assembly operations, inspection data, and personnel involvement remain connected through documented records.

Regulatory audits require manufacturers to trace backward to defective lots, assembly errors, or supplier batches within limited timeframes.

Barcode systems, manufacturing execution systems, and technician identification badges support real time data capture.

Key Elements of Traceability Systems

Effective traceability systems rely on supplier data codes identifying component origin, purchase order and lot numbers linking inventory to builds, and in process barcoding capturing each manufacturing stage.

Inspection results and test outcomes must remain tied to serial numbers and process steps. Real time systems enable creation of a digital twin representing product configuration and production history.

Benefits of Robust Traceability

Robust traceability enables rapid root cause analysis during failures and supports confident responses during regulatory audits.

Recall scope becomes precise, limiting disruption and cost. Field fixes become easier to plan and verify.

Traceability also supports continuous improvement when connected with manufacturing execution systems and CAPA workflows.

Data trends reveal process weaknesses and guide preventive actions.

Manufacturing Considerations

Assembly Process Highlights

Medical PCBA assembly follows tightly controlled process steps. Solder paste application must meet defined thickness and alignment criteria.

Surface-mount or through-hole component placement requires verified programs and calibrated equipment.

Reflow soldering profiles demand validation to prevent component damage or solder defects. Post-assembly cleaning removes residues critical to long-term reliability and patient safety.

Conformal coating or potting protects assemblies operating in harsh or humid environments. Final assembly includes permanent traceable marking using serial numbers or barcodes.

Quality Assurance and Testing

Quality assurance integrates in process inspection with automated optical inspection and X ray analysis. Functional testing and stress testing confirm performance under expected operating conditions.

Process validation activities include Installation Qualification, verifying equipment setup, Operational Qualification, confirming operating ranges, and Performance Qualification demonstrating consistent output.

Cleanroom operation reduces contamination risk and supports the stringent cleanliness standards required for medical electronics.

Cost vs Compliance

ISO 13485 compliance requires investment in infrastructure, training programs, and digital systems. Initial costs often appear significant when compared to commercial electronics manufacturing.

Hidden costs of non-compliance include regulatory penalties, forced recalls, delayed approvals, and reputational damage. Recovery expenses frequently exceed proactive compliance investments.

Return on investment appears through reduced defect rates, faster audits, predictable quality, and stronger customer trust. Compliance functions as a strategic business decision rather than a regulatory checkbox.

Summary

Traceability and documentation form mandatory foundations within medical PCBA manufacturing.

Patient safety, regulatory confidence, and long term product performance depend on disciplined recordkeeping and process visibility.

Partnerships with ISO 13485 certified suppliers help minimize product risk, embed quality into production, and maintain regulatory readiness.

Increasing device complexity and tightening regulations place traceability systems at the center of competitive and compliant medical electronics manufacturing.